Industries

Ask Our Team

Our client-focused team applies a breadth of knowledge and technical experience in engineering, quality assurance, and best-in-class procedures to meet the exacting standards of a diversified customer base.

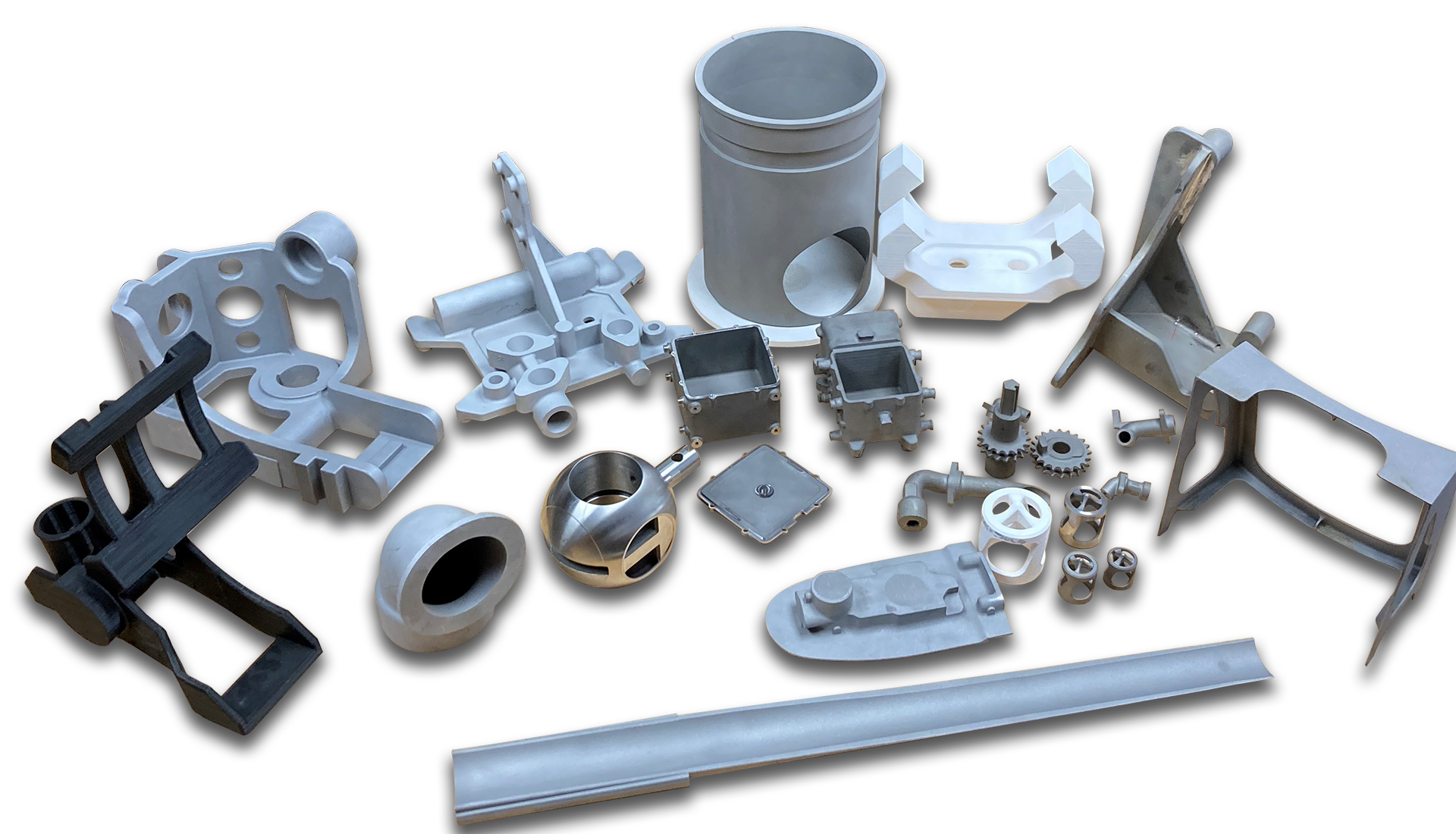

In-House Capabilities

DP Cast’s complete range of design and manufacturing capabilities promotes the enhanced “productibility” of your finished part.

Aerospace Quality

Our precision parts – and the processes behind them – are built to meet aerospace industry specifications and standards.

Quality Assurance

DP Cast is qualified as a Laboratory Control at Source and Non-Destructive Testing at Source provider.

Product Assistance

We don’t just execute your design – we influence it through applied engineering, prototyping, tooling, thorough review, testing and design innovation.

Mold-Making

No matter your requirement, at DP Cast, we have the ability to maintain, repair and modify your molds as required.

Non-Destructive Testing

DP Cast provides Level III, CGSB, ASNTSNT-TC-1A and NAS410-certified personnel, equipment and facilities, to all of our customers, regardless of sector.

Melt & Pour

All of our castings are produced onsite from molds made at our facilities in Brampton, Canada and poured from our 5 melt furnaces.

Alloys

At DP Cast, we pour a wide range of alloys, including plain carbon and low-alloy steels, stainless steels, and non-ferrous alloys, such as aluminum, bronze and cobalt.

Zero failure tolerance

is our constant.

Get a better view into our in-house, aircraft quality, custom offering and process.